JCL Machinery

Since the late 1960s, JCL had been building machines such as press machines and feeder for the glass industry. Due to increasing project requirements since 2000, JCL began to joint-venture with its partners in China to produce a wide range of machineries for the glass industry, including press machines, annealing lehr, blowers etc. Other than offering customers with a lower cost option for machines, JCL has been continuously working on the improvements of its machine products, through technical tie-up with European and Japanese manufacturers. JCL is active in listening to customers' feedback and as such is able to introduce many improvements to its machines. By 2009, JCL became the sole manufacturer in China to produce annealing lehr of international standard.

Today, JCL supplies a wide range of machineries for the glass industry as follow:

Feeder - Gob Feeder Machine

The feeder is used for feeding glass gob onto IS machine or other production machinery for glass production.

Servo Feeder

The Servo Feeder System offers the ability to improve production quality and customize the gob forming. This feeder comprised of mechanical transmission system, servo motor driving unit, synchronous and display system; which are integrated with the control cabinet of spinning machine; it is designed to deliver good glass gobs to the spinning machine.

Technical Specifications:

-

Servo Shear Cut and Lubrication Cooling System (Spraying System)

-

Shear Cut is synchronized with production line

-

Servo Plunger Mechnism

-

Maximum Stroke: 250mm

-

Maximum Working Stroke: 220mm

-

Vertical Speed (min/max): 0 / 500mm/s

-

Revolving Tube rotation controlled by Invertor

-

Revolving Tube Rotation Speed (min/max): 2/10rpm, bi-directional

-

Cast Iron Spout with Manifold

-

Gob Rejection System

-

Electronic Control Panel whereby Feeder movement, job paramaters and CAM profile can be programmed

Mechanical Type Feeder FD-141 Gob Feeder

The mechanical type gob feeder provides a cheaper solution while fulfiling all glass feeding function. Plunger and shear are cam-driven. Synchronized Motor are used for synchronizing all lines .

Technical Specifications:

-

Output 28TPD (Shallow Spout)

-

Weight of Gob: 20-1500 g

-

Plunger Height Adjustment: -20 ~ +100mm

-

Revolving Tube Speed: 3 ~ 12 rpm invertor control

-

Revolving Tube Adjustment: 0 ~ 75mm

-

Spout Open width: 410mm

-

Spout Depth: 216 mm

-

Power: 2.7 kW

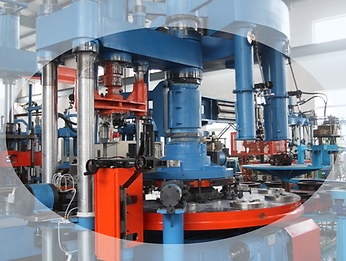

Press Machine

JCL develops and manufactures various models of press machines according to customers' need. Since the founding of our company in 1952, we have produced more than 100 press machines for the glass industry, including JP-12, JP-16, JPK-12, JPKD-12 and JPDG-24.

These machines can be used for producing glass tumblers, bowls, plates, tea cups, beer mugs, water jugs, juice blenders etc. Customers can choose the most suitable press machine models based on their own specifications and requirements. We have a team of highly-skilled glass production professionals and machinery experts ready to provide any technical assistance and to build the most suitable press machine for the glass plants.

Standard:

-

Geneva Indexing or Index Cam

-

Automatic Lubrication System

-

Electronic Timer

-

Pneumatic, Hydraulic or Servo Pressing

-

Automatic Takeouts

Option:

-

Hinged Mold Linkage

-

Delivery Equipment

Fire Polishing Machine

Horizontal Type Fire Polisher LFM38

The horizontal type fire polisher is generally used for fire polishing the glass tumbler.

Technical Specifications:

-

Fuel:LPG or Natural Gas

-

Number of Stations : 38

-

Pitch : 250 mm

-

Station Rotation Method : Linear Rotation Type

-

Mode of Station Rotation : Bi-Directional (both forward and reverse rotation polishing)

-

Burner : 6 Sets of Burners

-

Fuel for burner : Oxygen + Natural Gas

-

Uses Air Cylinder for glass push-out system.

-

Pushing stroke : 500 mm

-

Glassware is rotating during fire polishing

-

Machine Speed : max. 45 pcs/min

-

Max. Ware Diameter : 254mm

-

Max. Ware Height : 200mm

-

Fire polisher moves step-by-step (index-type drive) and is synchronized with press machine

-

Speed Control : By Schneider Invertor

-

Power : 5.5 KW

-

Weight of Fire Polisher : 3,500 kg

Rotary Type Fire Polisher FM20-150

The rotary fire polisher is generally used for polishing glass plates or bowls.

Technical Specifications:

-

Station:20

-

Table size: Ø1500

-

Pitch Circle Diameter (PCD): Ø 1350

-

Burner : LPG+O 2

-

The ware is constantly turning during fire polishing.

-

The Fire Polisher is synchronized with the press machine with speed controlled by invertor

-

Power: 4KW

Cross Conveyor (SBT250-40C)

The Cross Conveyor is used for cross conveying glass tableware to an annealing lehr. The machine adopts the balance point-wheel step-less reducer and the tooth chain. It has the advantages of wide speed range, smooth production through no skidding, long life span, a stable structure and ease of maintenance and repair.

Technical Specifications:

-

Conveyor Length : 4m

-

Belt width : 250 mm

-

Belt height : 900~1100 mm

-

Belt speed: 1.5~5m/min

-

Stepless inverter speed control

-

4 pcs of belt fire heat-gun

-

Power: 1KW

Conveyor Belt

With more than 30 Years experience in manufacturing conveyor belts, we are able to design belts to reduce friction and spiral "locking".

Our belts are manufactured with precision and accuracy to ensure smooth and stable feeding of glassware. High Quality Stainless Steels were used to prevent marking and staining.

Lehr Belt material available: AISI 321, 302, 304, 304L, 316, 316L, 310, 310S, 314, 410 & 2080

Spinning Machine

The spinning machine can be used for producing glass tableware such as plates, bowls etc. Its advantage over the press machine is that the glass thickness can be thinner and glass weight can be less, producing light weight glass tableware. Spinning machine is used especially in glass opalware production. We produce two types of spinning machine: Continuous Type Spinning Machine and Index-Type Spinning Machine

Continuous Type Spinning Machine

Continuous Type Spinning Machine is used when you need to produce glass in higher speed and higher production volume.

Technical Specifications:

-

No. of Stations : 12/16/18

-

Speed: 16~60 pcs/min

-

Turntable driven by Siemen Servo Drive System

-

Individual servo drive for mould spinning machine ( maximum speed = 1600 rpm )

-

Guide Guide Centering System

-

Mould Cooling Control System

-

Mould Temperature Measurement System (optional)

Index Type Spinning Machine

Index Type Spinning Machine is used when you need to produce glass in lower production volume.

Technical Specifications:

-

No. of Stations :6/8/12

-

Speed: 10~28 pcs/min

-

Glass Output: 4 ~ 16 T/D

-

Max Size of Glass Product: Ø330mm x 200mm H

-

Compressed Air: 4 m3/min, 6 Bar

-

Cooling Fan: 15200 m3/h, 60mBar

-

Electric Power: 85 kW, 400 Volt, 50 Hz

Push Stacker

H-28 Press and Blow Machine

The H-28 press and blow machine is used for producing glass stemware, tumbler etc by means of press and blow process. The entire system comprises of the feeder, H-28 machine, Burn-off Machine (BOM), Conveyor and Stacker System

H-28 Machine

Technical features:

-

No. of Stations : 12 or 18

-

Max. Speed: 45 pcs/min or 80 pcs/min

-

Plunger and Blank Mould Cylinder controlled by Electronic Valve

-

Blowing controlled by Electronic Valve

-

Flow Adjusted by Throttle Valve

-

Siemens SIMOTION Servo Control System

Burn off Machine (BOM)

Technical features:

-

No. of Stations : 24

-

7 zone burn off mechanism

-

Can prevent lip-point from forming in glass

-

SIemens SIMOTION Servo Control System

PB-10 Press and Blow Machine

The PB-10 Machine is a specialized machine used for producing glass jug using press and blow process.

PB-10 Machine

Technical features:

-

Pressing Stoke: 70~305mm

-

Max. Pressing Force @3.5 bar: 2,750 kg

-

Spout shaping mechanism for producing bent lip using gas oxygen burner and pneumatic-powered shaping tool

-

Turntable driven by Cam indexing

-

Automatic Lubrication System

-

Flow Adjusted by Throttle Valve

-

Siemens SIMOTION Servo Control System

Rotary Glass Bottle Forming Machine

The rotary glass bottle forming machine has 1 blank station and 4 rotary blow stations. Unlike IS (Individual Section) machine which is used for high volume production, the rotary glass bottle forming machine is suitable for small volume production of glass bottles.

Technical features:

-

Production Speed: 5 ~ 12 pcs / min

-

1 Blank Station and 4 Rotary Blow Stations

-

Siemens SIMOTION Servo Control System

Annealing/Decorating Lehr

Our annealing and decorating lehrs are suitable for the heat treatment of glass containers and tableware after forming. The purpose of the annealing lehr is to relieve the stress in the glass containers after forming. The purpose of the decorating lehr is to allow chemical bonding of the print onto the glass containers, after printing.

In order to achieve temperature homogeneity in the lehrs, they are designed with the following specifications:

-

Fans: All heating and cooling zones are equipped with air circulating fans.

-

Burners: Venturi-type On/Offf burners are used to ensure even heating and temperature control.

-

Inner Wall: Heat resistant stainless steel (AISI 409L or AISI 304) is used for all inner walls of each zone.

-

Belt Material: 1Cr13 or AISI 304 stainless steel

-

Thermocouple: Stainless Steel Sheathed Ni Cr type K thermocouple is installed in each zone

-

All the temperature control meters on the control panel are imported from Japan, model TM225 and Belt speed is controlled by invertor from Fuji, Japan.

Tempering Lehr

Our tempering lehrs are used for the heat treatment of glass tableware in order to increase their mechanical resistance towards impact and thermal resistance from high temperature change. This helps to prevent cracking or shattering of glass tableware if they are dropped onto the ground, or from shattering if they are put in high temperature, e.g. microwave oven

Belt-Type Tempering Lehr

Our Belt-Type tempering lehr is suitable for the tempering of glass plate and bowl. The design of

preheating zone and heating zone are similar to that of annealing lehr with circulating fan. After the heating zone, all the glass articles require immediate and even cooling-down in order to toughen the glass plate. The cooling ducts with adjustable pressure cooling air are provided. Each cooling duct is connected through air pipes to a rectangle box which has many small air tubes. The rectangle air tubes are positioned above and below the glass article in order to cool down both sides of the glass article evenly.

Spindle-Type Tempering Lehr

Our Spindle-Type tempering lehr is suitable for the tempering of glass tumbler

and bowl. This lehr consists of 3 zones as follow:

1. Preheating Zone. With 4m conveyor and 5 sets of burner firing, where the rotating glassware are preheated to high temperature.

2. Heating Zone. Through 15m heating tunnel constructed with refractory and 16 burners, the glassware is heated up to about 680°C evenly.

3. Tempering Zone. 5 Sets of high pressure air cooling chamber are designed to quench the

glassware from the top, bottom and both sides evenly.

Glass Cullet Crusher

The glass cullet Crusher is used for crushing glass into cullet, which is then re-used as a raw material in glass melting. We provides two types of glass cullet: hammer-type and jaw-type crushers.